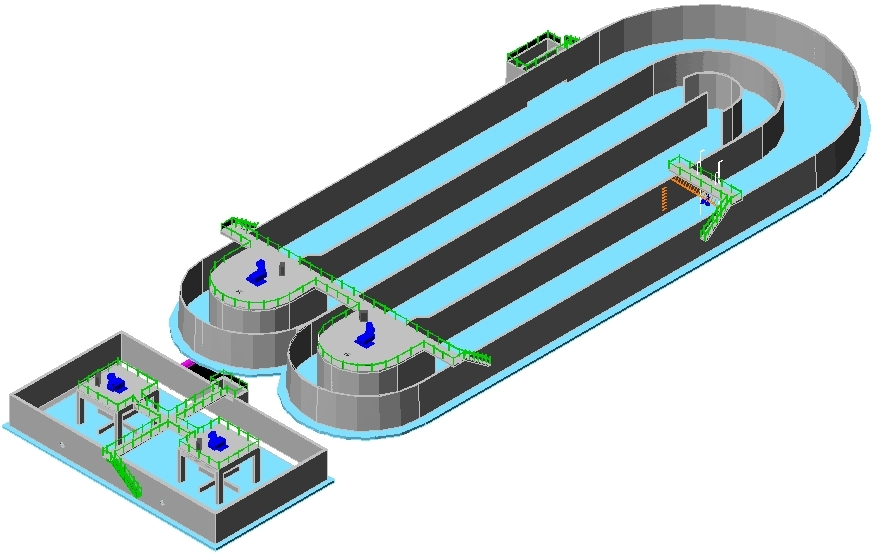

AB-CARROUSEL®

The AB-CARROUSEL® is an advanced version of the CARROUSEL® oxidation ditch system, especially designed for treatment of industrial wastewater (Paper and pulp, petrochemical, food-processing etc.). The AB-CARROUSEL® consists of two intrinsically connected units that have both been developed by DHV: the Anti Bulking Reactor (ABR™) and the CARROUSEL®.

The development of Anti-Bulking Reactor comes out of the experience from operation of many industrial wastewater treatment plants which are often bothered by bulking sludge and, as a consequence, loss of biomass (MLSS) and deterioration of effluent quality. Filamentous bacteria with poor settling properties that feed on easily biodegradable COD are quite often the basic cause of this phenomenon. |

AB-CARROUSEL® |

The two distinguished parts of the AB-CARROUSEL® are complementary. The ABR™ is a kind of chemostat with a hydraulic residence time of 4 to 10 hours. Only the fastest growing bacteria will survive. Because of this fast growing they only oxidise the easily biodegradable COD and leave the slowly biodegradable components untouched. In the CARROUSEL® the remaining part of the COD is effectively removed. As a result the bulking sludge problems are solved quickly and permanently in the AB-CARROUSEL® and effluent requirements are met.

In practice, beside the disappearance of bulking sludge problems, three additional side effects are observed. The oxygen demand, the land requirements and the sludge production of the AB-CARROUSEL® decrease with approximately 25% compared to conventional treatment systems. This, in turn, considerably decreases the investment and operation costs. |